- +44 118 370 2004

- info@powertekuk.com

- +1 631 824 4666

- info@powertekus.com

DCflex dc current probe

The DCflex dc current probe measures large DC currents up to 100,000A and very easy to use because of its fast-wrap-around probe. Used where busbars prevent clip-on-type rigid current clamps, testing current sharing in large buses in electro-chem applications

Description

- Optional large current sense coils

- compact sense coil easily threaded between bus bars and cables

- Intrinsically safe, galvanically isolated measurement

- Battery powered with integral LCD display, no need for external oscilloscopes or meters

- Easy to use, fast measurement

- System shutdown not necessary

- Supplied with lanyard, case, calibration certs

- Thin flexible current sensor, clip around sense coil available in lengths of 1m, 2m and 4m

The DCflex dc current probe is an easy to use, economical, clip-around, split core DC current probe. It is ideal for the measurement of large DC currents with models from 2000A to greater than 300,000A. It is ideal for the analysis of large dc currents in plating, chemical processes and aluminum smelting plant, can be easily verified without system shutdown or installing shunts

The probe takes a single shot measurement of the dc current with a typical accuracy of better than 1%.

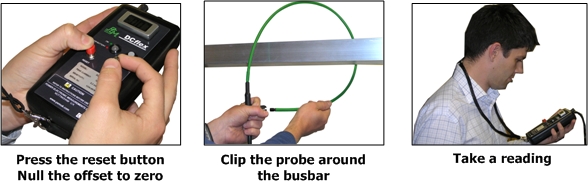

Easy Clip Operation

As the sense coil is clipped around the conductor, it creates a current pulse from DC

.jpg)

How the DC Flex works

The Rogowski sense coil responds to a change of current - from zero to the DC current value flowing, this action is created by the user wrapping the coil around the conductor. Once the user has performed this action the DC Flex's peak hold meter holds the dc current measurement. The signal conditioner (aka integrator) is supplied with a meter and zero adjustment which is set before a measurement is made. The DCFlex's instantaneous output provides a useful output for ac ripple measurement - connecting to any oscilloscope

When ordering please provide the following information

Maximum dc current

Sense Coil length 1000mm (~310mm dia) or 2000mm (~630mm dia)

Cable length from sense coil to meter/integrator (1.5 metre standard)

Insulation 2kV standard (supplied with silicone sleeve)

Power supply 12Vdc - 24Vdc as standard, supplied with 120Vac or 240Vac adapter

i.e. DCFlex / 10kA / 1000 = 10000Adc, 12-24Vdc power, 1.5 metre cable, 1000mm sense coil

Contact Powertek today