High Current DC Amps Sensors, rugged split core construction for Arc Furness Smelting, Electro-chemistry, Rail Transport, Welders and DCS

Converting large dc current to an isolated voltage or current loop, optional Modbus interfaces

These High current CTH sensors convert dc (dc to LF) currents to an isolated voltage or mA output with instantaneous precision

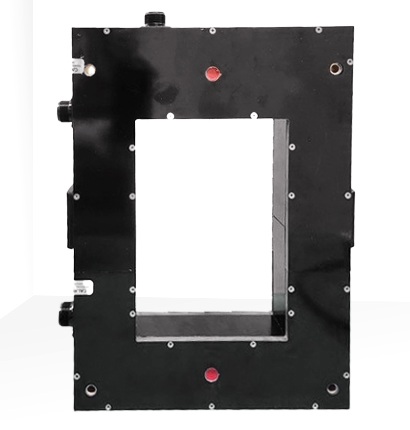

CTH split core Type G

Type G split core DC-1kHz- CTH Hole size 76.2mm (3.0") x 165.1mm (6.5"). Outer 196.85mm (7.75") x 304.8mm (12.00")

- Current ranges 1000 / 2000 / 3000 / 4000 / 5000 / 6000A

CTH non-split core Type FL

Type FL DC-50kHz- CTH aperture 200mm (7.9") x 100mm (3.93"). Outer 332mm (13.1") x 176.1mm (6.93")

- Current ranges 5000 / 7500 / 10000 / 12000 / 15000 / 28000 Adc

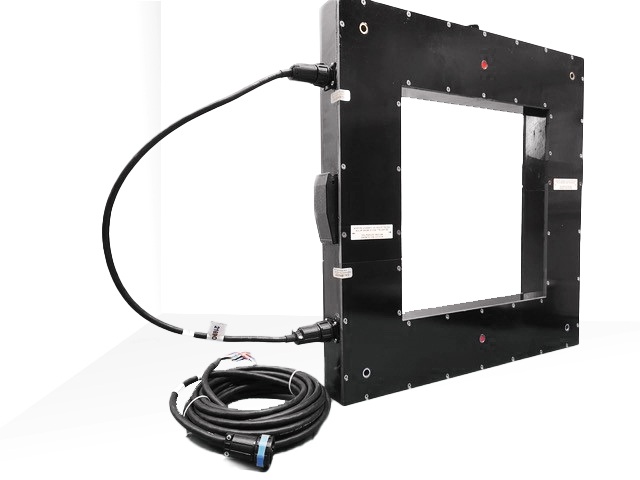

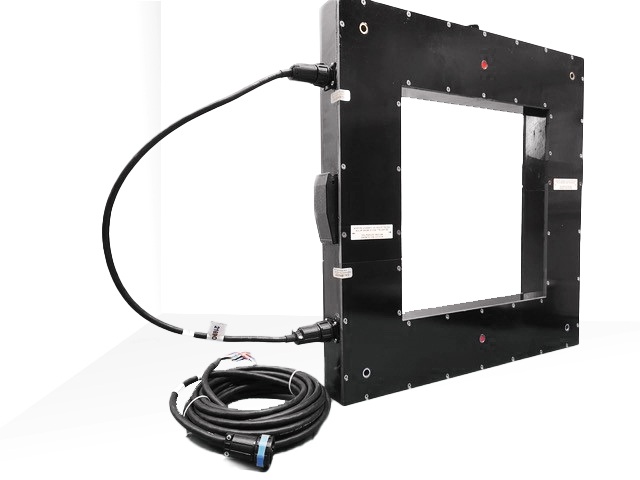

CTH split core Type 10

Type 10 & 11 split core DC-1kHz- CTH Hole size 140mm (5.5") x 203mm (8"). Outer 254 (10") x 350 (13.75")

- Current ranges 5000 / 6000 / 7000 / 8000 / 9000 / 10000 / 15000 / 20000A

CTH split core Type 11

Type 10 & 11 split core DC-1kHz- CTH aperture 330mm (13") x 330mm (13"). Outer 534mm (21") x 534mm (21")

- Current ranges 25000 / 30000 / 35000 / 40000Adc

The CTH current sensors convert very large dc currents, dc amps to an isolated voltage or mA output with high precision and response times. The CTH Type 10 and Type 11 output is a faithful reproduction of the measured current, whether ac or dc. All popular EV (Electro vehicle) types, process control voltage and current loop outputs are available. Modbus over ethernet allows quick hook-up to DAQs. Through hole or split core options mean that connection is non-intrusive, straightforward and fast to install. The available Amps input range of the CTH sensors is any value from 1A to 40000Adc. Optional dc offset control allows nulling of residual dc current to ensure best use of the output span. The sensor power input is designed to operate over a wide voltage range associated with process control and sub-station auxiliary dc supply systems. Active Hall Effect sensor technology allows measurement from DC-1kHz (depending on the sensor type) along with fast step response. The CTH Type 10 can also be used to provide an instantaneous output for ac currents. Typical applications are found in process control systems like PLC or SCADA, transportation, telecommunications, dc drives, welding, arc furness and circuit breaker testing. For all CTH models, a NIST/NPL (UKAS) traceable calibration certificate and certificate of conformance is supplied.

Type 10: 140mm (5.5") x 203mm (8") 5000A - 20000A Sensor connects to signal conditioner via 2.4M cable

Type 11: 330mm (13") x 330mm (13") 25000A - 40000Adc Sensor connects to signal conditioner via 2.4M cable

Longer cable lengths available - on request

The order code is based on:-

CTH / amps input / output / SC or TH / power input + core type

SC = split core, TH = through hole (non-split core)

Note: 230Vac/dc and 115Vac/dc adapters are available (in this case the CTH will be supplied with 9-36Vdc input and ac adapter)

Options R : Ruggedization (not available for all sensor types)

Option T : Extended temperature range -40°C - 85°C (not available for all sensor types)

Options : noise rejection and offset, user can specify upper or lower frequency –3db point

Non standard input current

Non standard output voltage, current (25mA, 1A, 5A), USB, RS485 and WiFi interfaces available

All models constructed with self extinguishing materials to UL94V0 and CSA

CTH / 400A / 10 / TH / 48Vdc type 4

±400Adc input, ±0-10V output, through hole, 48Vdc aux power input core type 4 (50mm hole dia)

CTH / 800A / 5 / SC / 9-32Vdc type 8 RS485

±800Adc input, ±0-5V output, split core, 9-32Vdc aux power input, core type 8 (50mm hole dia) RS485 interface

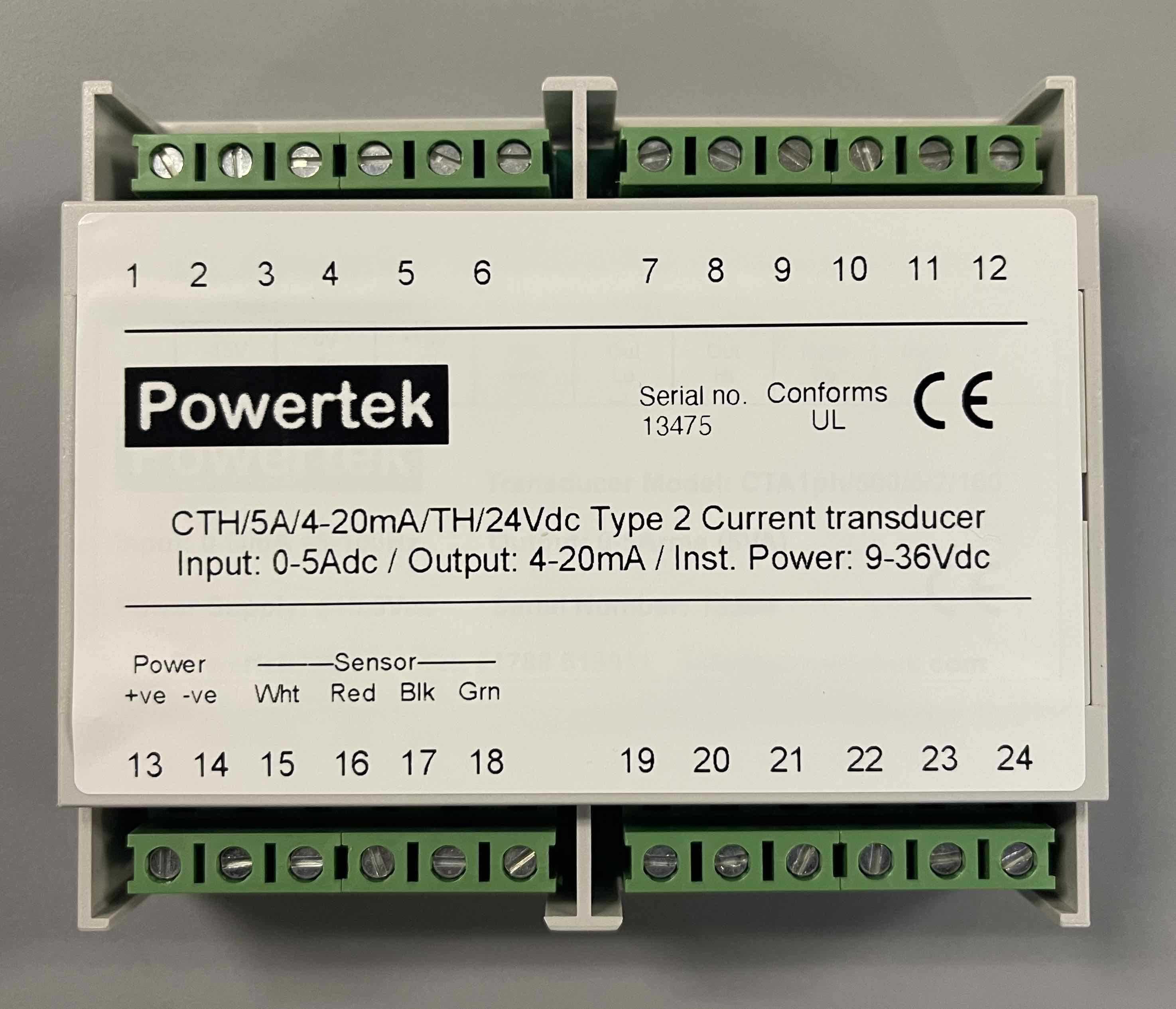

Signal conditioner terminal connections

Terminals numbers used in DC Current Transducer Config:

Inst. Power: 13/14 +ve/-ve | Sensor 15(wht) 16(Red) 17(blk) 18(Grn)| Outputs: 7/8 4-20mA 9/10 0-10V (7, 9 grounds)

Input and output grounds are isolated 300V

Signal conditioner overall size 106mm (4.187") x 90mm (3.5") x 32mm (1.25")

Cookie Consent

We use cookies to enhance your browsing experience, serve personalised ads or content, and analyse our traffic. By clicking "Accept All", you consent to our use of cookies.