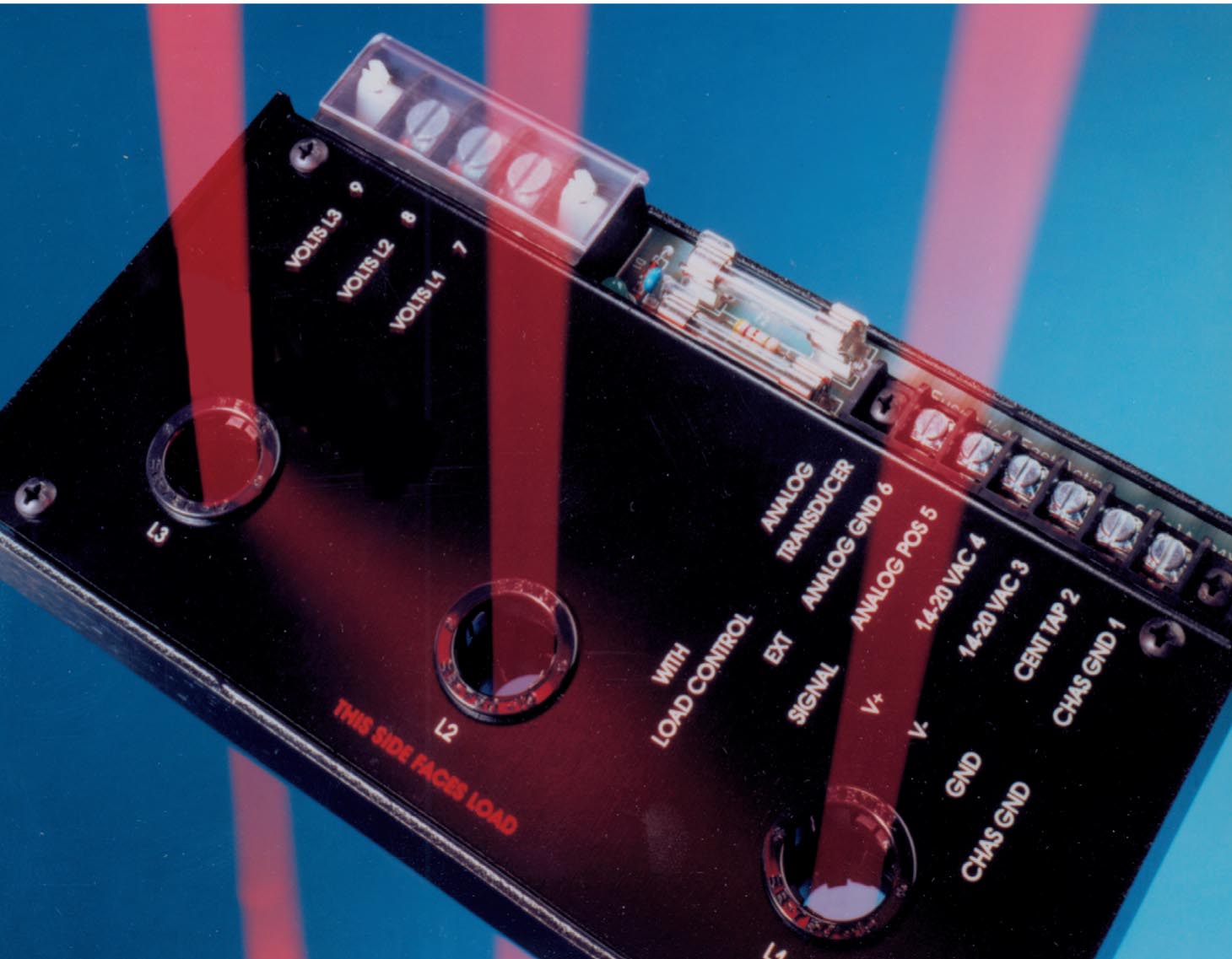

PH-3A and PH-1000 Power and Horse Power HP Transducers

Active Power, Horse Power (HP) and Current Sensing for Variable Speed Motors and Wide Ranging AC/DC Loads

Highlights

- Power Cells are stand-alone power transducers

- Ideal for Machine Tool, obstruction sensing and Viscosity

- Analog output proportional to power (HP horsepower or watts kW)

- Self-contained power transducer, no current or voltage transformers

- Versatile, works with both fixed and variable frequency power

- Optional 230V and 460V power available

- Adjustable response 0.06 to 1sec, standard 15ms

- Non contact current connection

- Certified to NIST and UKAS

General Information

Fast Response PH-3A Power Cell

- Ideal for machine tool applications

- Monitor fast load changes

- Self-contained – No PTs or CTs to install

PH-1000 Power Cell for Large Loads

- Monitor motors up to 1000HP

- 1-3/4" conductor openings

- No PTs or CTs to install

Specifications

| Full Scale Capacity 460 Volt Network | ||

| Model | Full Scale | kW Scale |

| PH-3A-HHG | 2HP | 1.5 |

| PH-3A-HG | 4.5HP | 3.3 |

| PH-3A-10 | 10HP | 7.5 |

| PH-3A-15 | 14HP | 10.4 |

| PH-3A-20 | 21HP | 15.7 |

| PH-3A-30 | 32HP | 23.9 |

| PH-3A-40 | 43HP | 32.1 |

| PH-3A-50 | 53HP | 39.5 |

| PH-3A-60 | 64HP | 47.7 |

| PH-3A-70 | 75HP | 56 |

| PH-3A-80 | 85HP | 63.4 |

| PH-3A-90 | 96HP | 71.6 |

| PH-3A-100 | 107HP | 79.8 |

| PH-3A-350-140 | 149HP | 111.2 |

| PH-1000-100 | 102HP | 76.1 |

| PH-1000-200 | 213HP | 158.9 |

| PH-1000-300 | 320HP | 238.7 |

| PH-1000-400 | 427HP | 318.5 |

| PH-1000-500 | 533HP | 397.6 |

| PH-1000-600 | 640HP | 477.4 |

| PH-1000-700 | 747HP | 557.3 |

| PH-1000-800 | 853HP | 636.3 |

| PH-1000-900 | 960HP | 716.2 |

| PH-1000-1000 | 1067HP | 796 |

*KW=(HP)(.746)

** NOTE: The Current Networks do not limit the current. They provide the Full Scale Power calibration point (HP or KW). The Power Cell is not damaged by overloads.

| For Voltage Networks Other Than 460 Volt Multiply Full Scale HP by: | |

| 115 Volts | .25 |

| 185 Volts | .4 |

| 230 Volts | .5 |

| 255 Volts | .55 |

| 380 Volts | .83 |

| 415 Volts | .9 |

| 580 Volts | 1.26 |

The capacity can be reduced by taking additional "turns" with the wire through each hole for each phase.

Example: A 10HP unit is reduced to 5HP by taking two turns through each hole. It is reduced to 3.33HP with three turns, etc.

Outputs Available:0-1mA, 4-20mA, 0-5 Volts, 0-10 Volts the output is powered by the Power Cell

To Order:Specify Model Number, Network Voltage (if not 460 Volts) instrument power and output.

Power SensorsYou can understand the loading on an electric motor by measuring the electric current flowing to the motor (Amps rms). Typically this is not the best method since a lightly-loaded motor doesn't use the electricity very efficiently. In technical terms, the power factor is low

A better technique to understand the load is to measure the motor power, measured in Horsepower HP or Kilowatts (W). Motor power has a straight line relationship, so it works well even when the motor is lightly loaded.

Our PH Power Sensors measure the motor load (Horsepower or Watts) and send an analog signal to meters, Data Acquisition equipment, computers and PLCs. This way, the operator can see motor load status, the computer can make decisions.

The typical way to measure power is fairly complex. However, our PH Power Sensor gives users a simple accurate solution.

Load ControlsA PH power sensor measures motor power in kW, however, in addition, it has built-in relays and set points. The user can adjust the set point so that when the motor load reaches the set point, a relay will trip. The relay acts as a switch and is used to turn off the machine, sound an alarm, control other processes or adjust the machine feed rate.

Contact Powertek today

Cookie Consent

We use cookies to enhance your browsing experience, serve personalised ads or content, and analyse our traffic. By clicking "Accept All", you consent to our use of cookies.