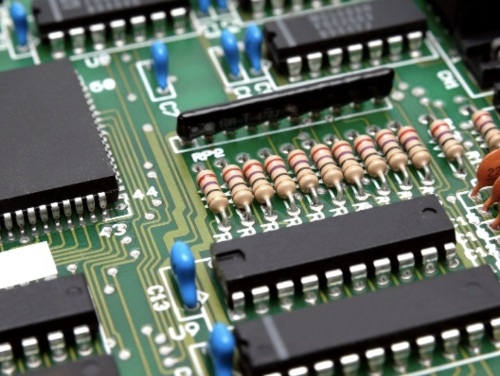

Electronic assembly, PCB prototyping, PCB assembly, through hole and mixed component

Small batch PCB prototyping and manufacture

- Specializing in small batch

- Prototype manufacture

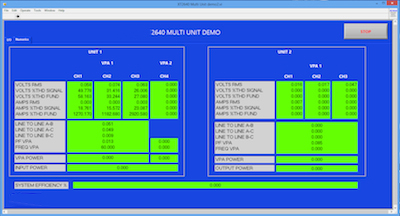

- Prototype functional test

- Prototype test and calibration

- Small SMT assembly, PTH assembly, SMT+PTH mixed

- PCB design and PCB Fabrication

- Component Sourcing & Turnkey PCB Assembly

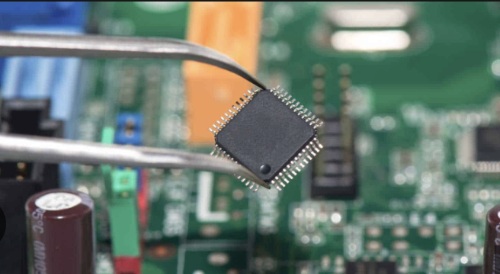

- IC Programming & PCBA Testing

- ISO9001:2015 Compliant, ISO 13485:2016 Certified & UL Listed materials

- 100% AOI, X-RAY

- No MOQ & Competitive Pricing

Powertek UK Ltd combined with WASPS PCB Services Reading UK to offer small batch PCB services and assembly. PCB assembly is short for printed circuit board assembly, which means soldering electronic components on to a printed circuit board.

Usually, both SMT assembly and PTH assembly are used in a completed electronic PCB assembly. Here, we would like to introduce a little about SMT assemblies, PTH assemblies and other methods of PCB assembly services as a UK PCB assembly supplier. SMT assembly is short for surface mount technology assembly, which means assembling electronic components on the PCB by surface mount technology. The normal processes of SMT assembly are printing solder paste on the printed circuit board by solder stencil first; then placing the relative components on the surface of the PCB; and lastly, passing the PCB with components through a reflow soldering oven, so the solder paste will be melted and the components will be soldered. It is the most widely used PCB assembly services method because of its high efficiency and accuracy.

PTH assembly is short for plated through hole assembly, which means soldering the electronic components on the PCB by soldering their pins in the PTH holes. Both wave soldering and manually soldering can be used in printed circuit board assembly. The normal processes for PTH assembly are: inserting the pins or legs of the PCB components into the through holes of the PTH firstly and then passing the PCBs through the wave soldering equipment with hot liquid solder; lastly the components are soldered in the PTH holes when the solder is cooled down. This is the other most widely used PCB assembly services technology.

Although SMT assembly and PTH assembly are the two most popular methods used by printed circuit board assembly suppliers, we can also just solder the PTH components on the PCB manually with a soldering iron; this is the third most commonly used PCB assembling method - suited for small batch manufacture. But it is impossible for mass production since the efficiency of manual printed circuit board assembly is very low.

Typically one single PCB board assembly may contain all mixed PCB assembly technology, so PCB assembly companies require expertise in all these techniques. Powertek-Wasps is a custom PCB designer-assembler-manufacturer in Reading UK, having experience in all kinds of PCB assembly. We focus on small to medium volume PCB manufacturing and PCB assembly in Reading UK with 21 years of experience. Our factory is ISO9001, ISO13485 compliant and uses only UL certified materials.

More Content TBA

- Small Quantity for functionality proving and testing

- Ideal for pre-manufacture prototype quantities

- Mixed component types with through hole and surface mount

- Fitting retrospective options

- Small batch updates and upgrades

Cookie Consent

We use cookies to enhance your browsing experience, serve personalised ads or content, and analyse our traffic. By clicking "Accept All", you consent to our use of cookies.